What is an Autoclave?

An autoclave is a versatile piece of equipment used in various industries for sterilization. While autoclaves come in different sizes, shapes, and functionalities, their core method for sterilization remains the same: high-temperature steam and pressure. Scientific and medical laboratories, sterilization is a critical part of maintaining a safe and clean environment. One of the most essential tools for this purpose is the laboratory autoclave. The terms steam sterilizer and autoclave are synonymous and can be used interchangeably. That said, autoclave is often used in laboratory settings, while sterilizer is more commonly heard in hospitals or pharmaceutical settings.

Also Read Us: Grab Bucket Manufacturer in India

Working Principle of Autoclave

The working principle of an Industrial autoclave is based on the use of high-pressure steam to sterilize items by killing microorganisms such as bacteria, viruses, and spores. Here’s a simplified breakdown of how it works:

1. Sealing and Pressure Build-Up

- The items to be sterilized are placed inside the autoclave chamber.

- Once the chamber is sealed, steam is injected into the chamber, raising both temperature and pressure.

- The pressure inside the autoclave is increased (typically 15-20 psi above atmospheric pressure), allowing the steam to reach temperatures higher than boiling water (usually around 121°C or 250°F).

2. Sterilization Phase

- The combination of heat and pressure penetrates the items in the chamber, destroying microorganisms by denaturing their proteins, enzymes, and other essential components.

- The high temperature ensures that all forms of microorganisms, including bacterial spores, are killed.

3. Maintaining Temperature and Pressure

- The autoclave maintains the high temperature and pressure for a specific duration (usually 15-30 minutes) to ensure thorough sterilization of all items inside.

4. Depressurization and Drying

- After the sterilization phase, the pressure is slowly released, and the steam begins to condense, leaving behind dry items.

- Some autoclaves also include a drying cycle to ensure that no moisture remains on the sterilized items.

5. Safe Removal

- Once the cycle is complete and the pressure is released, the items are safe to be removed from the autoclave, now fully sterilized and ready for use.

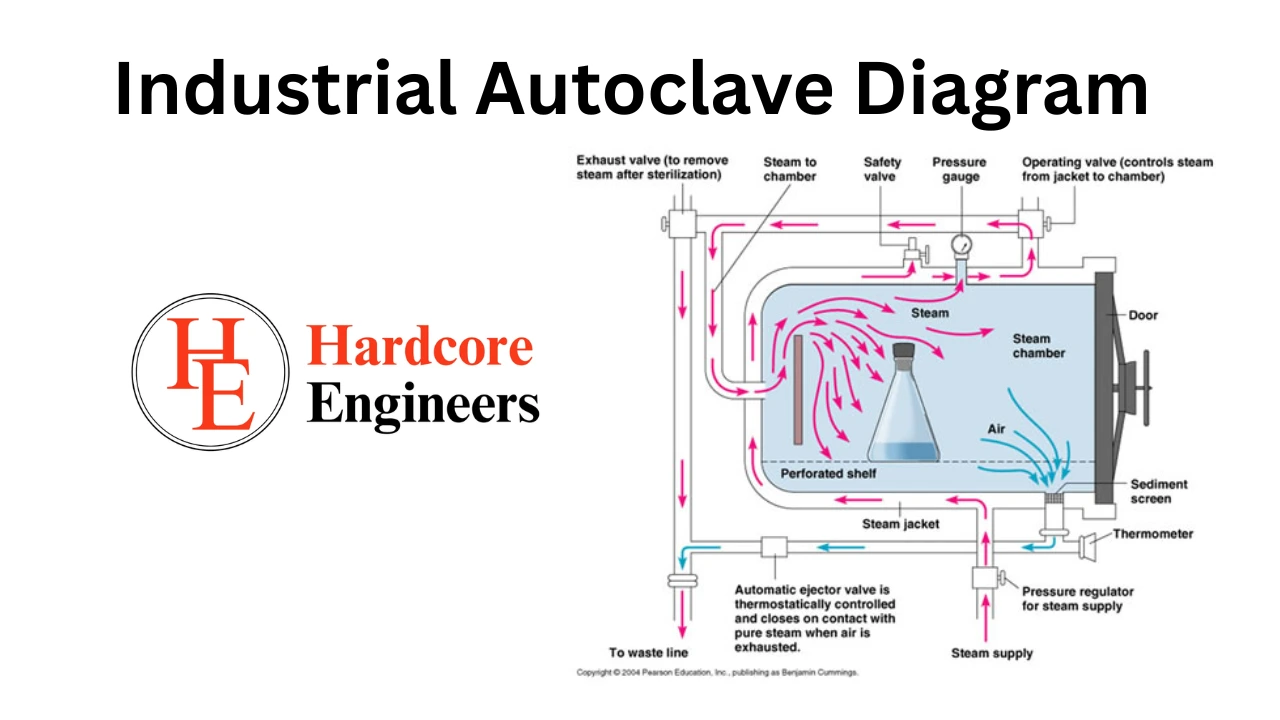

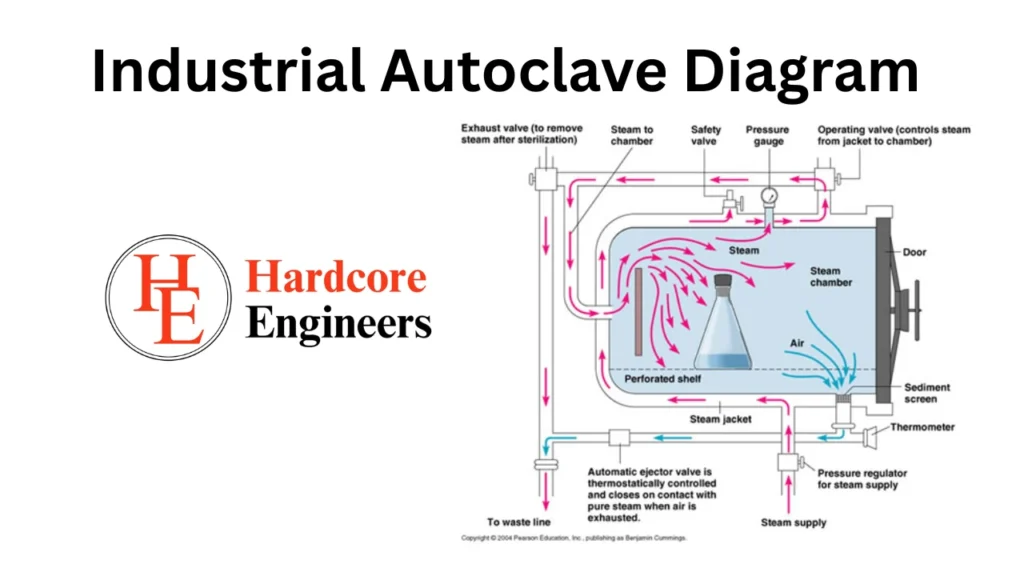

Basic Diagram of an Autoclave:

An autoclave typically consists of the following components:

- Chamber:

- The main body where items are placed for sterilization. It’s a sealed, pressure-resistant container that holds the materials to be sterilized.

- The main body where items are placed for sterilization. It’s a sealed, pressure-resistant container that holds the materials to be sterilized.

- Pressure Relief Valve:

- A safety mechanism that helps control the pressure inside the autoclave and prevents over-pressurization.

- A safety mechanism that helps control the pressure inside the autoclave and prevents over-pressurization.

- Heating Element:

- This component generates steam by heating water, which is then injected into the chamber. It ensures the temperature inside the chamber is high enough for sterilization.

- This component generates steam by heating water, which is then injected into the chamber. It ensures the temperature inside the chamber is high enough for sterilization.

- Steam Inlet Valve:

- A valve that controls the flow of steam into the autoclave chamber, helping to maintain the required pressure and temperature for sterilization.

- A valve that controls the flow of steam into the autoclave chamber, helping to maintain the required pressure and temperature for sterilization.

- Thermometer or Temperature Sensor:

- This sensor monitors the internal temperature to ensure the autoclave operates at the correct sterilization temperature.

- This sensor monitors the internal temperature to ensure the autoclave operates at the correct sterilization temperature.

- Vacuum Pump (in some models):

- Used in vacuum autoclaves, it removes air from the chamber before steam is introduced, allowing for better penetration into porous items.

- Used in vacuum autoclaves, it removes air from the chamber before steam is introduced, allowing for better penetration into porous items.

- Control Panel:

- The interface used to set parameters like temperature, pressure, and cycle time. Modern Industrial autoclaves often feature digital controls for automated operation.

- The interface used to set parameters like temperature, pressure, and cycle time. Modern Industrial autoclaves often feature digital controls for automated operation.

- Drain Valve:

- This valve allows the condensed steam (water) to exit the chamber once the sterilization cycle is complete.

- This valve allows the condensed steam (water) to exit the chamber once the sterilization cycle is complete.

- Door:

- A tightly sealed entry point that prevents steam from escaping during the process.

Conclusion :

As a leading Industrial Autoclave manufacturer, Hardcore Engineers focused on product quality, which enhanced the working ability of our autoclave. We manufactured Different types of autoclaves designed to meet the specific needs of laboratories, from small-scale operations to high-volume environments. The right autoclave choice depends on factors like space, the types of materials being sterilized, and throughput requirements. If you are looking for purchase any kind of autoclave such as industrial autoclave, laboratory autoclave and more, Hardcore engineer is here for all kinds of needs.